Niobium Supplier, Manufacturer & Exporter in India

Amardeep Steel is a leading niobium supplier of niobium, a chemical element with the symbol Nb and atomic number 41. It is a soft, gray, ductile metal that belongs to the transition metals group. Known for its high melting point and excellent corrosion resistance, niobium plays a crucial role in various industrial applications. Its corrosion-resistant nature allows it to maintain stability in harsh environments, while its high melting point of 2,468°C (4,474°F) makes it ideal for high-temperature uses. Additionally, niobium is highly valued for its superconducting properties, allowing it to conduct electricity without resistance at extremely low temperatures. This makes it essential for producing superconducting magnets used in MRI machines and particle accelerators.

Niobium is also prized for its strength and lightweight, often alloyed with steel to improve its strength and durability. As a result, niobium alloys are frequently used in industries such as aerospace, where they help build high-performance components, and in steel production, where it enhances the toughness and corrosion resistance of pipelines and construction materials. Amardeep Steel, recognized as a reliable niobium alloy supplier, ensures the delivery of high-quality niobium alloys for diverse industrial applications. Despite its relative rarity, with most mining occurring in Brazil and Canada, niobium’s unique properties make it an indispensable material in many advanced technologies.

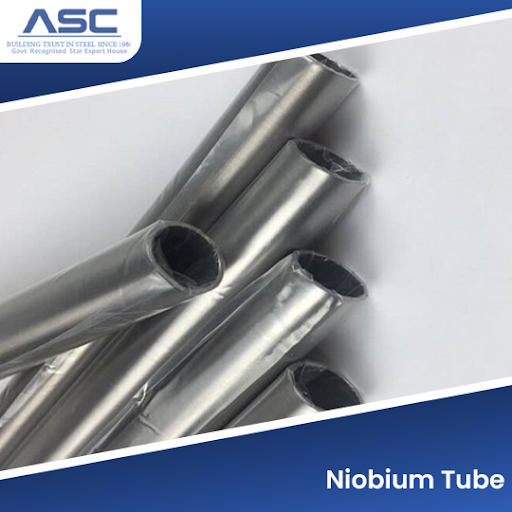

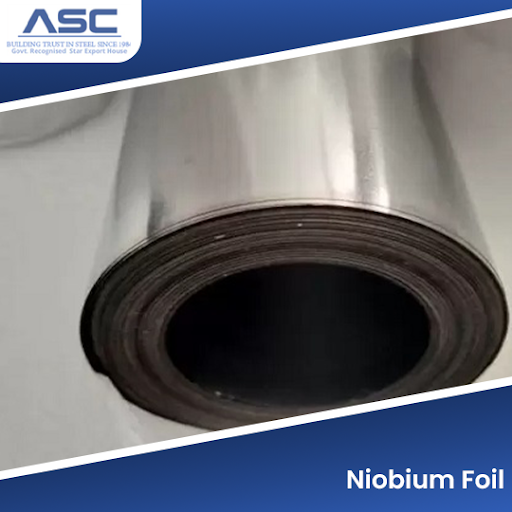

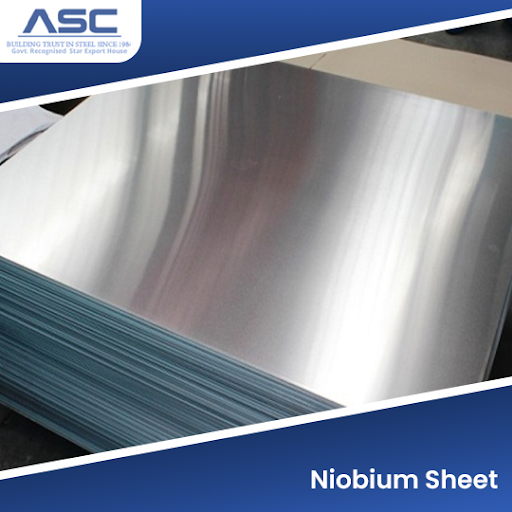

Niobium Products List

Specifications of Niobium

| Attribute | Value |

|---|---|

| Form Factor | Wire, Target, Pipe, Ingot, Tube, Foil, Sheet |

| Purity | Typically ≥ 99.6% (commercial grade), ≥ 99.9% (high-purity/reactor grade) |

| Manufacturing Method | Vacuum arc, electron-beam melting for high purity |

| Applicable Standards | ASTM B393 (sheets/plates), ASTM B391 (ingots) |

Chemical Composition of Niobium

Aluminium is well-known for its electrical conductivity, making it ideal for electrical applications.

| Element / Impurity | Maximum Content (wt%) |

|---|---|

| Tantalum (Ta) | 0.05 |

| Tungsten (W) | 0.007 |

| Titanium (Ti) | 0.005 |

| Molybdenum (Mo) | 0.005 |

| Hydrogen (H₂) | 0.0002 |

| Nitrogen (N₂) | 0.0010 |

| Oxygen (O₂) | 0.0010 |

| Carbon (C) | 0.0010 |

| Other impurities | ≤ 0.003 each |

Niobium Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | ≥ 140 MPa (sheet standard) |

| Yield Strength (0.2% offset) | 50 – 100 MPa |

| Elongation at Break | ≥ 30% |

| Vickers Hardness (HV10) | ≤ 603 |

| Modulus of Elasticity | ~105 GPa |

| Yield/Tensile Strength (range) | 207–585 MPa (varies by form) |

Niobium Physical Properties

| Property | Metric |

|---|---|

| Density | 8.57 g/cm³ |

| Melting Point | ~2,410–2,468 °C |

| Boiling Point | ~5,000 °C |

| Thermal Conductivity | ~53.7 W/m·K |

| Thermal Expansion | ~7.3 µm/m·K |

| Crystal Structure | Body-centered cubic |

| Electrical Resistivity (0 °C) | ~152 nΩ·m |

Applications of Niobium

Niobium is widely used across industries due to its high strength, corrosion resistance, and superconductivity:

- Steel & Construction: Adds strength and toughness to pipelines, bridges, skyscrapers, automotive bodies, and ship hulls.

- Superalloys & Aerospace: Found in jet engines, rockets, and gas turbines for high-temperature durability.

- Superconductors & Electronics: Used in MRI magnets, particle accelerators, high-performance capacitors, and quantum tech.

- Optics & Electronics: Niobium oxide boosts lens clarity; lithium niobate powers RF filters, sensors, and electro-optics.

- Medical: Biocompatible and corrosion-resistant, used in prosthetics, implants, and MRI equipment.

- Nuclear & Energy: Used in reactor components, fusion device magnets, and withstands extreme conditions.

- Battery Technology: Emerging use in fast-charging EV batteries, enabling lighter, more efficient designs.

Frequently Asked Questions

1. What are the Properties of Niobium?

Pure niobium is a soft and ductile metal, resembling steel in appearance and platinum when polished. It boasts excellent corrosion resistance; however, it is prone to oxidation at temperatures exceeding approximately 400°C (750°F). Niobium is most effectively dissolved in a mixture of nitric and hydrofluoric acids.

2. Is niobium cheaper than titanium?

Yes, niobium is generally cheaper than titanium. While titanium is known for its superior corrosion resistance, niobium is more affordable and widely available. Additionally, niobium is one of the most inert metals, making it an excellent hypoallergenic choice for body jewelry, especially for individuals with sensitive skin.

3. Which is better, titanium or niobium?

Niobium has a smoother surface finish than titanium, which can help prevent irritation, especially for earring posts. Although niobium is less common and often more expensive than titanium, it can also be anodized in a wide range of colors.

4. What is niobium mainly used for?

Niobium is primarily used in alloys, including stainless steel, where it enhances strength, especially at low temperatures. Alloys containing niobium are commonly found in jet engines, rockets, structural beams, and girders for buildings and oil rigs, as well as in oil and gas pipelines. Additionally, niobium exhibits superconducting properties, making it valuable in various high-tech applications.