Know The Difference Between Nickel 200 & 201 Grades

by Vidhi Gada

Posted on February 15, 2022 at 02:05 PM

We take a closer look at Nickel 200 and Nickel 201, two alloys that provide great corrosion resistance and adaptability, allowing them to be used in a variety of applications.

Nickel, abbreviated as "Ni," is a significant element of stainless steel that is solely responsible for its parent alloy's strength and hardness. Stainless steel accounts for more than two-thirds of all nickel produced worldwide. Though nickel is found in varying degrees in all forms of stainless steels, such as duplex and precipitation hardened steel, it is particularly important in the SS 300 series, where it stabilizes the austenitic (face-centered cubic lattice) phase in the core structure. SS-304 and SS-316, which contain roughly 8-10% and 10-13% Nickel, respectively, are two of the most important grades among them. Nickel is present in 75 percent of all stainless steel products accessible worldwide.

Nickel 200 and Nickel 201 are commercially pure nickel grades, meaning they contain at least 99 percent nickel. Iron, silver, manganese, copper, carbon, and sulfur, in minuscule, defined amounts, make up the final 1% or less.

Low-alloy materials provide benefits over other materials in some industrial applications because they are low-alloy. Nickel is "effectively and extensively recycled" because of its worth, according to the Nickel Institute, and nickel materials help to make "existing goods and processes more energy efficient, durable, and tough." This implies it is utilized more sustainably than other metals and metal alloys, and it is managed responsibly throughout its existence.

Nickel 200 and Nickel 201 are both often used in a variety of industrial applications. Because of the high concentration of high-quality nickel, Nickel Grades are resistant to a wide range of reducing agents and caustic alkalies, and they have outstanding electrical and thermal conductivity. The materials are also some of the hardest metals on the market, with good magnetic characteristics. Both grades of the material are similar in many aspects, with consistent specifications that make them a desirable option for a wide range of applications.

The carbon concentration within the composition is the fundamental variation between the two Grades. Nickel 201 is a low-carbon variant of Nickel 200, with a maximum carbon content of 0.02 percent as opposed to 0.15 percent. As a result, they're frequently used for significantly distinct purposes. "The Nickel 200 and Nickel 201 have their own qualities, and they are generally presented as a dual-certified Nickel 200/201." This allows a customer to combine the strength of Nickel 200 with the compositional stability.

Nickel 200:

Nickel 200 has good ductility and weldability, as well as outstanding mechanical qualities. It also has good magnetic and magnetostrictive properties, as well as good thermal and electrical conductivities, a low gas content, and a low vapour pressure. It's used in a variety of situations where the temperature is less than 315°C (600°F).

Its corrosion resistance is not restricted to reducing elements – though this is where it excels – as it also performs well in some oxidizing circumstances.

Nickel 200 is a material that is frequently used in the electronics sector. This is a fast-paced industry where new components are constantly being developed. As a result, low-alloy nickel is in high demand. Anode plates, passive cathodes, plater bars, transistor enclosures, and other components can all benefit from Nickel 200. Some optical systems, such as those used in telescopes, as well as infrared emitters in cameras and surveillance systems, contain it. It can also be utilized in battery connections and heating elements.

Because of its great corrosion resistance, it's also utilised in chemical shipping drums, where it may keep its structure and integrity even when corrosive media assault it. This is beneficial for both storing and transporting volatile compounds. Nickel 200 is used in food processing and synthetic fiber processing systems, for example.

Nickel 200 is also used in the aerospace sector and for military purposes. This contains missile-related components.

Nickel Alloy 200 Chemical Composition:

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

|---|---|---|---|---|---|---|---|

| Nickel 200 | 0.15 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

Alloy 200 Mechanical Properties:

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Nickel 200 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

Nickel 200 Equivalent Grades:

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| Nickel 200 | 2.4066 | N02200 | NW 2200 | NA 11 | НП-2 | N-100M | Ni 99.2 |

Nickel 201 is a kind of nickel that is used in:

Nickel 201 shares many of the same characteristics as Nickel 200. It's better for applications where the temperature will be higher than 315°C (600°F). Because it has a lower carbon concentration than Nickel 200, it will not produce graphite after prolonged exposure to high temperatures.

It has a low work-hardening rate and a low base hardness, making it ideal for spinning and cold shaping. It has strong corrosion resistance and is commonly used to handle caustic soda because it generates an oxide covering that protects it.

Nickel 201 is well-known for its application in the caustic alkali concentration (chloralkali) process, which is used in a variety of industries. This procedure generates chlorine and sodium hydroxide (caustic soda), and the entire process is extremely corrosive. Nickel 200 is a popular material for making cathode elements because of its exceptional resistance to caustic alkalies. Nickel 200 can also be utilized in this technique, although higher-temperature settings require the lower-carbon Nickel 201. This application is discussed in greater depth here. Evaporators and extraction components are among the applications for the chloralkali process.

Nickel 201, like Nickel 200, is employed in the food processing industry due to its resistance to distilled and natural fluids. It aids in the preservation of product purity, which is critical when working with food.

Nickel 201 is commonly used in pressure vessel service, which are containers that carry gases or liquids at a pressure that is much higher than the ambient pressure. The ASME Boiler and Pressure Vessel Code Section VIII-Division I has approved it for this use up to 1250°F (about 677°C).

Nickel Alloy 201 Chemical Composition:

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

|---|---|---|---|---|---|---|---|

| Nickel 201 | 0.02 max | 0.35 max | 0.2 max | 0.01 max | 0.25 max | 0.4 max | 99.0 min |

Alloy 201 Mechanical Properties:

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Nickel 201 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

Nickel 201 Equivalent Grades:

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| Nickel 201 | 2.4068 | N02201 | NW 2201 | NA 12 | НП-2 | - | NLC-Ni 99 |

Comparison Of 200 & 201:

APPLICATIONS

Nickel 200 is a corrosion-resistant metal that is utilized in the processing of foods, synthetic fibers, and caustic alkalies, as well as in structural applications. Chemical shipping components, electrical and electronic parts, as well as aircraft and missile components, all use it.

Caustic evaporators, combustion boats, plater bars, and electronic components are all made of nickel 201. For applications involving temperatures above 600oF (315oC), it is a better choice than nickel 200.

FORGING

Both grades will be forged between 2200 and 1600 degrees Fahrenheit (1205 and 870 degrees Celsius), but mild forging may be done below 1200 degrees Fahrenheit (650 degrees Celsius) to improve mechanical qualities.

THE USE OF HEAT

As a recovery from cold work, the alloy is annealed at temperatures ranging from 1100oF (595oC) to 1700oF (925oC), depending on the metal's mechanical working history. To keep the metal's look, controlled atmospheres should be used.

Long-term exposure of Nickel 200 to temperatures between 800 and 1200 degrees Fahrenheit (425 and 650 degrees Celsius) will result in graphite precipitation. For such applications, nickel 201 should be used.

MACHINABILITY

Material that has been annealed tends to generate lengthy, stringy chips, whereas material that has been cold worked is easier to machine. Tools made of high-speed steel or cast-alloy are preferred.

WELDABILITY

Traditional techniques can be used to weld Nickel 200 and Nickel 201, although oxy acetylene welding should not be utilized on Nickel 201 due to the risk of carbon pickup.

When it comes to Nickel 200/201, it's a no-brainer

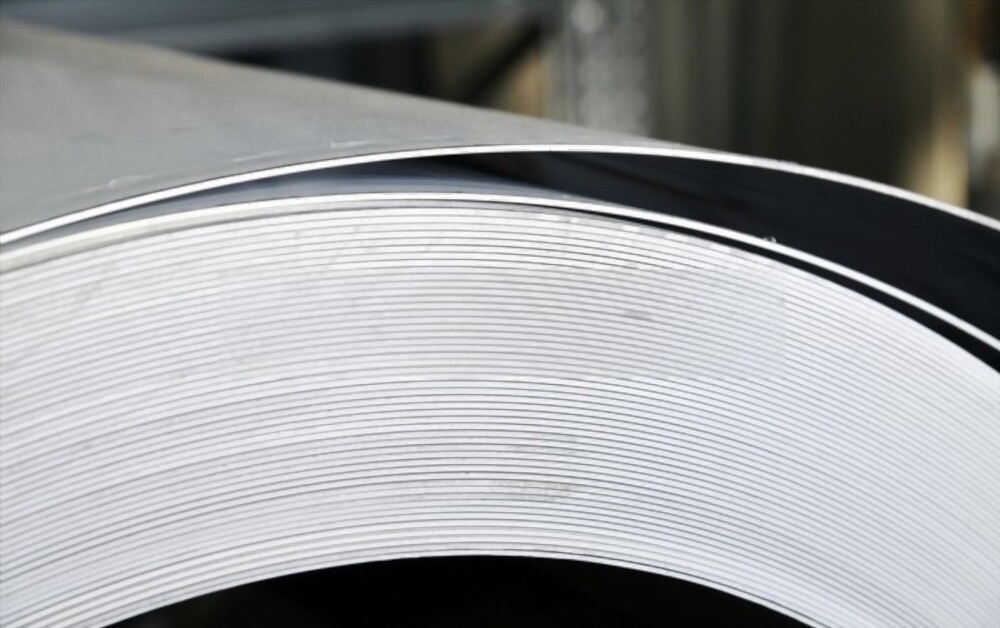

They can be hot molded into practically any shape, which increases their versatility and use. Nickel 200 and Nickel 201 come in a variety of shapes and sizes, including pipes, tubes, sheets, strips, plates, round bars, flat bars, and wire.

All regular cold-forming methods can be used on them, and they can be machined and welded using standard commercial processes. Correct annealing and operating techniques allow these essential materials to retain their ductility and strength.

What Is Alloy Steel? Characteristics And Applications

Alloy steel is a versatile material that finds widespread use in construction and various industries.