254 SMO Products Manufacturer & Supplier in India

As a premier 254 SMO products supplier and stockist in India, we specialize in providing high-quality, high-performance super austenitic stainless steel. Our SMO 254 products list (UNS S31254) is a highly alloyed material with low carbon content, specifically designed for use in aggressive, chloride-rich environments like seawater.

Alloy 254 SMO's unique composition, which includes high levels of chromium, molybdenum, and nitrogen, gives it exceptional strength—almost double that of conventional 300 series stainless steels. This makes it a robust and reliable choice for demanding applications, offering superior resistance to pitting, crevice corrosion, and stress corrosion cracking. In addition to its strength and corrosion resistance, Alloy 254 SMO is prized for its high ductility and excellent impact toughness, even at low temperatures. It is often a cost-effective alternative to more expensive nickel and titanium alloys, without compromising on performance. The "6% Moly" designation for this family of alloys highlights its high molybdenum content, which is key to its outstanding corrosion-resistant properties.

The alloy's good weldability and formability allow for easy fabrication and enable its use in a variety of complex shapes. In its annealed state, Alloy 254 SMO also exhibits non-magnetic properties, a crucial characteristic for certain specialized applications.

Due to these features, Alloy 254 SMO is a preferred material in industries such as chemical processing, offshore oil and gas, power generation, and desalination plants.

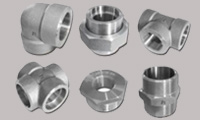

SMO 254 Products

254 SMO Chemical Composition

The chemical composition of Alloy 254 SMO is carefully balanced to achieve its superior properties.

| Element | Content (%) |

|---|---|

| Iron (Fe) | Balance |

| Chromium (Cr) | 19.5 - 20.5 |

| Nickel (Ni) | 17.5 - 18.5 |

| Molybdenum (Mo) | 6.0 - 6.5 |

| Nitrogen (N) | 0.18 - 0.22 |

| Carbon (C) | Max 0.02 |

254 SMO Mechanical Properties

The mechanical properties of 254 SMO demonstrate its high performance and durability.

| Properties | Metric | Imperial |

|---|---|---|

| Tensile Strength | 680 MPa | 98600 psi |

| Yield Strength | 300 MPa | 43500 psi |

| Elongation at Break | 50% | 50% |

| Hardness, Brinell | 210 | 210 |

| Modulus of Elasticity | 195 GPa | 28300 ksi |

| Poisson’s ratio | 0.30 | 0.30 |

254 SMO Material Equivalent

Equivalent grades for 254 SMO (UNS S31254) include:

| Standard | Equivalent Grade |

|---|---|

| EN Number | 1.4547 |

| W.Nr. | 1.4529 |

| AFNOR | Z1 CNDU 20.18.06AZ |

254 SMO Melting Point

| Property | Value |

|---|---|

| Melting Point | 1320-1390°C |

| Density | 8.0 g/cm³ |

254 SMO Heat Treatment

- Hardening: 254 SMO does not harden with heat treatment. It can only be hardened through cold reduction.

- Annealing: Annealing should be performed at a temperature of 1149-1204°C (2100-2200°F). This process must be followed by a water quench.

- Hot Working: Forging and other hot working operations can be carried out between 982-1149°C (1800-2100°F).

254 SMO Applications

SMO 254 is used in a wide range of applications, including:

- Seawater handling and desalination plants

- Flue gas desulfurization scrubbers

- Pulp and paper industry bleaching equipment

- Chemical process equipment

- Tall oil distillation columns

- Food processing equipment

- Oil and gas production components

To get a complete SMO 254 products price list or a specific SMO 254 products price, please contact our sales team. Our dedicated staff will provide you with a precise quotation tailored to your project’s specific requirements.

Frequently Asked Questions About SMO 254

What is SMO 254 material?

SMO 254 is a high-alloy austenitic stainless steel. It is also known as a "6% Moly" steel due to its high molybdenum content, which gives it exceptional resistance to pitting and crevice corrosion.

Is 254 SMO magnetic?

In its annealed state, SMO 254 is non-magnetic. As a high-alloy austenitic stainless steel, it maintains a stable austenitic structure, which is not ferromagnetic. However, like many austenitic grades, some slight magnetism can be induced by cold working or severe deformation, though it generally remains non-magnetic for most practical applications.

What are the benefits of using SMO 254?

The main benefits are its outstanding resistance to stress corrosion cracking, pitting, and crevice corrosion, combined with high strength and good weldability. It offers a more cost-effective alternative to expensive nickel-based alloys in many applications.

How does SMO 254 compare to 316L stainless steel?

SMO 254 offers significantly better corrosion resistance than 316L, especially in chloride environments. Its strength is also nearly double that of the 300 series stainless steels.