Properties and Advantages of Corten Steel

by AMC

Posted on Novermber 12, 2024 at 05:01 PM

Your materials can make or break the outcome regarding construction and outdoor design projects. One material gaining popularity over the years is Corten Steel Material, This type of Corten steel is known for its unique aesthetic appeal, durability, and corrosion resistance. In this comprehensive guide, we’ll explore the properties and advantages of Corten Steel, to help you decide if it’s the right Corten Steel material for your next project.

What is Corten Steel?

Corten Steel (sometimes known as weathered steel) is a group of steel alloys that are often used in outdoor construction. Corten Steel was designed to eliminate the need for painting and if left outside, exposed to the elements, they will develop a rusted appearance in just a few months. COR-TEN Steel refers to the two distinguishing properties of this type of steel: corrosion resistance and tensile strength. Corten steel material is most popular among architects due to its enduring, earthy patina. This distinctive Corten Steel has been refined to enhance its strength and durability, making it a preferred choice in contemporary architecture and sculpture.

COR: Corrosion-Resistance

TEN: Tensile Strength

The alloys which make up corten are primarily copper and chromium.

The way Corten Steel is combined allows the steel to retain a high degree of strength and create natural rust (patina) that protects it from atmospheric elements that commonly cause corrosion and structural damage.

The rust-coating it develops also gives it a natural-looking and ruggedly beautiful appearance.

Its anti-weathering, high-strength and aesthetically pleasing properties make it an ideal metal for outside construction and landscaping projects.

Properties of Corten Steel

Corten steel, also known as weathering steel, has many properties, including

Paint Durability — While many manufacturers prefer Corten’s rustic look as it is, it can be painted in the same manner other steels are painted in, but it requires a less frequent repainting cycle due to its lower rust rate.

Weldability — Since it has a low carbon content, the steel remains pliable enough for welding.

Workability — Corten steel can be cold-formed, hot-formed, and gas-cut, making it easy to work with no matter what the project requirements are.

Reliability — It displays 2-8 times more anti-corrosive resistance than regular steel, is 1 ½ – 10 times more paintable than common carbon steel, and has a tensile strength of no less than 445 MPa, making it a high-performance, long-lasting material for steel parts.

As you can see, such qualities are particularly useful for outdoor projects.

It should be noted here that weathering steel comes in two grades – Corten A and Corten B – which exhibit some or all of the above properties to a larger or lesser extent.

|

Property |

Description |

Value or % |

|---|---|---|

|

Tensile strength |

High and can withstand significant stress without deformation |

470 – 630 MPa |

|

Yield strength |

Strong and can maintain structural integrity and its original shape under stress |

310 – 345 MPa |

|

Elongation |

Excellent and forms an external oxidized layer or patina to protect from rust and corrosion |

6 – 12 months for the initial layer of patina |

|

Corrosion resistance |

High and allows the steel to stretch without breakage |

~20% |

Corten Steel Composition

Corten steel naturally undergoes a chemical process that creates a new surface composition that offers more atmospheric corrosion protection than other steels can provide.The unique composition and distribution of alloying elements within corten steel form continuous self-regenerating rust that protects the surface from oxidation and corrosion.

Corten steel is made up of iron, carbon, and small amounts of other elements, including:

|

Destination |

Steel grade |

Designation |

C |

Si |

Mn |

P |

S |

Cu |

Ni |

Cr |

Other elements |

γ value |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

For domestic uses |

Highly weathering steel product |

COR-TEN O |

≤0.12 |

0.25–0.75 |

0.20–0.60 |

≤0.035 |

≤0.035 |

0.25–0.55 |

≤0.30 |

0.30–1.25 |

— |

— |

|

Unpainted specifications for welded structures |

COR-TEN 490A/B/C |

≤0.17 |

0.30–0.65 |

0.80–1.25 |

≤0.035 |

≤0.035 |

0.30–0.50 |

0.05–0.65 |

0.30–0.65 |

V:0.02–0.10 |

— |

|

|

Weathering steel product |

COR-TEN 570 |

≤0.17 |

0.40–0.80 |

1.25 |

≤0.035 |

≤0.035 |

0.30–0.40 |

0.05–0.45 |

0.30–0.65 |

V:0.02–0.10 |

— |

|

|

General weathering steel product |

NAW™ 490 |

≤0.12 |

0.15–0.35 |

≤0.90 |

≤0.035 |

≤0.035 |

0.25–0.50 |

— |

— |

ΣTi:0.15 |

— |

|

|

Ni-type highly weathering steel |

Highly weathering steel product |

NAW-TEN12 -400A/B/C |

≤0.18 |

0.15–0.65 |

≤1.25 |

≤0.035 |

≤0.035 |

0.50–1.00 |

— |

0.70–1.70 |

— |

1.2 |

|

NAW-TEN12 -490A/B/C-570 |

≤0.18 |

0.15–0.65 |

≤1.40 |

≤0.035 |

≤0.035 |

0.50–1.00 |

— |

0.70–1.70 |

— |

1.2 |

||

|

For overseas uses |

Highly weathering steel product |

COR-TEN A |

≤0.12 |

0.25–0.75 |

0.20–0.60 |

≤0.035 |

≤0.035 |

0.25–0.55 |

≤0.30 |

0.30–1.25 |

— |

— |

|

Unpainted specifications for welded structures |

COR-TEN B |

≤0.19 |

0.30–0.65 |

0.80–1.25 |

≤0.035 |

≤0.035 |

0.30–0.50 |

0.05–0.65 |

0.30–1.25 |

V:0.02–0.10 |

— |

|

|

Weathering steel product |

COR-TEN C |

≤0.19 |

0.30–0.65 |

0.80–1.25 |

≤0.035 |

≤0.035 |

0.30–0.50 |

0.05–0.65 |

0.30–1.25 |

V:0.04–0.10 |

— |

This table represents the chemical composition percentages for different grades and types of Corten steel, based on their intended use (domestic or overseas) and weathering properties. The elements are represented in their ranges and limits as per the specifications the provided in table.

Corten Steel Mechanical Properties

| Grade | Position of sample | Min. yield strength (MPa) | Tensile strength (MPa) | Min. total elongation [%] | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| e² ≤ 16 | e² > 16 | e² ≤ 3 | e² ≥ 3 | L₀ = 80 mm | 2 < e² ≤ 2.5 | 2.5 < e² ≤ 3 | L₀ = 5.65 √S₀ | e² ≥ 3 | ||

| S355J0WP | l/t | 355 | - | 510 - 680 | 470 - 630 | 16/14 | 17/15 | 18/16 | 22/20 | |

| S355J2WP | l/t | 355 | - | 510 - 680 | 470 - 630 | 16/14 | 17/15 | 18/16 | 22/20 | |

| S355J0W | l/t | 355 | 345 | 510 - 680 | 470 - 630 | 16/14 | 17/15 | 18/16 | 22/20 | |

| S355J2W | l/t | 3553) | 345 | 510 - 680 | 470 - 630 | 16/14 | 17/15 | 18/16 | 22/20 | |

| S355K2W | l/t | 3553) | 345 | 510 - 680 | 470 - 630 | 16/14 | 17/15 | 18/16 | 22/20 | |

Physical Properties of Corten Steel

| Weather resistant steel | Standard | Tensile Strength MPa | Yield Strength MPa | Elongation in 2 inches (min.) % |

|---|---|---|---|---|

| CORTENA | US steel | 470-630 | 355 | 20 |

| IRSM 41-97 | Indian Railways | 480 min | 340 min | 21 |

| ASTM A 588 | ASTM | 485 MIN | 345 min | 21 |

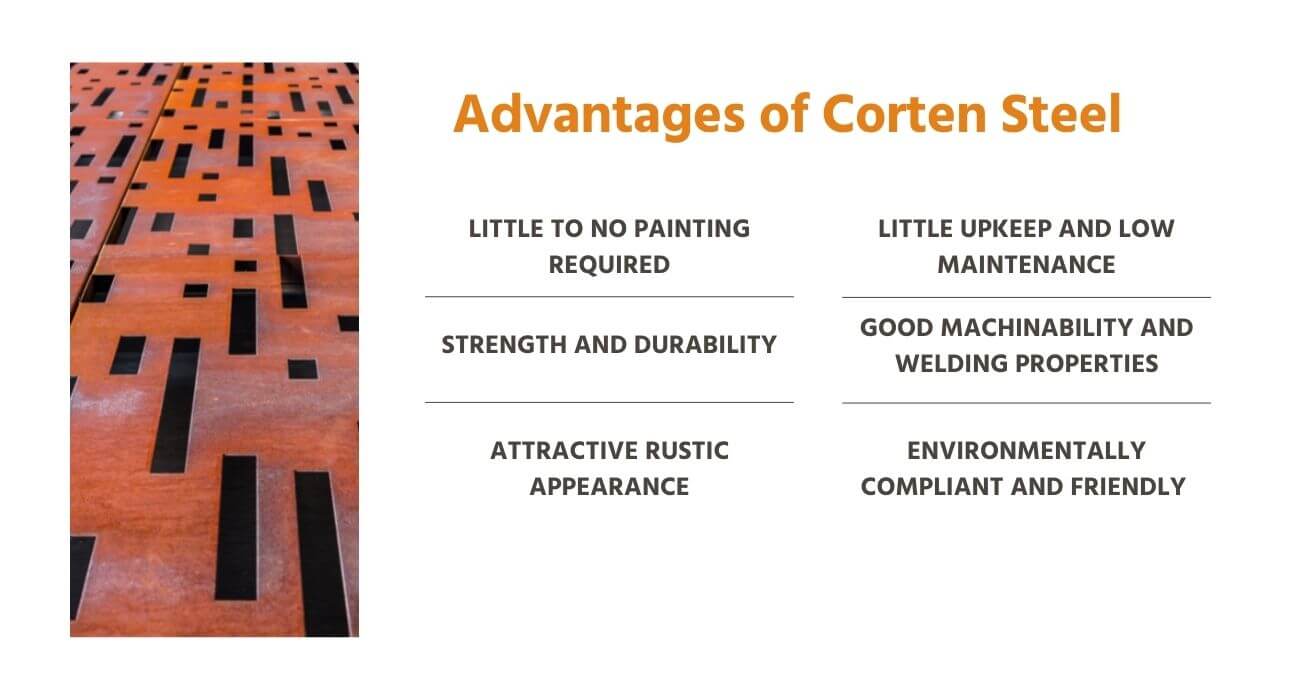

Advantages of Using Corten Steel

Weathering Steel’s anti-corrosive properties separate it from other steels, making it a better choice for outdoor metal parts and structures.

How is Corten Steel Made?

The corten steel manufacturing process begins with a blending of three primary plates of steel—copper, chromium, and nickel—along with other alloying elements like phosphorus, silicon, and manganese.

Very little carbon is used during the mixing process—less than 0.2-0.3 percent—to ensure pliability, strength, and toughness.

Combining these specific metals and elements results in a 1/4th inch thick sheet that is ductile enough to be formed into almost any desired shape.

The real magic of the corten steel process, however, occurs after the initial mixing takes place and during its natural weathering cycle.

Corten Steel Uses and Applications

Corten steel is widely used within the building and construction industry for large-scale projects as well as with medium to smaller projects where a high level of aesthetics is required (i.e., architecture, sculpture, home, and garden)

A summary of its more popular applications is given below:

Building & Architecture: outdoor load-bearing buildings, bridges, and ships, as well as architectural structures of an aesthetic nature, such as beach homes and museums.

Art, Sculpture, & Garden Design:outdoor art projects, especially those that include sculptures, as well as landscaping and garden structures exposed to damp and moist environments.

Visual Screens:cladding material for surrounding, dividing, and protecting structures like fences, gates, and wall panelings.

Aside from the above common uses, corten weathering steel is also utilized to create lesser-known and uncommon outdoor structures and applications.

Conclusion

Amardeep Steel provides Corten steel with unique properties and advantages, including natural corrosion resistance and a distinctive rust-like patina that strengthens over time. Its durability, low maintenance, and aesthetic appeal make Corten steel ideal for outdoor projects in architecture, landscaping, and art, offering a visually striking and long-lasting material solution.

FAQs

1. Is Corten steel expensive?

Yes, Corten steel is generally more expensive than mild steel, with costs averaging around 50% higher. However, its durability and natural corrosion resistance make it a worthwhile investment for many, especially in outdoor applications. To know more about Corten Steel Price please free to contact us.

2. What are the different types of Corten steel?

Corten A is lower in carbon, manganese, and silicon, and is often used for outdoor sculptures and aesthetic fascias. Corten B has more carbon than manganese and is often used for heavy-duty structures.

3. Does cor ten steel rust?

Yes, Corten Steel does rust, but in a controlled way. Within six months of exposure to the atmosphere, Corten steel forms a unique rust-like patina, which actually protects it from further corrosion. This rust layer, or patina, develops best under alternating wet and dry weather conditions and acts as a barrier that slows down future rusting.

Sheet Metal Gauge Chart

When working with sheet metal, the term "gauge" is commonly used to describe the thickness or thickness range of the material.