A Brief Guide to Understand Slip-on Raised face flanges

by Dinesh

Posted on August 28, 2018 at 12:30 PM

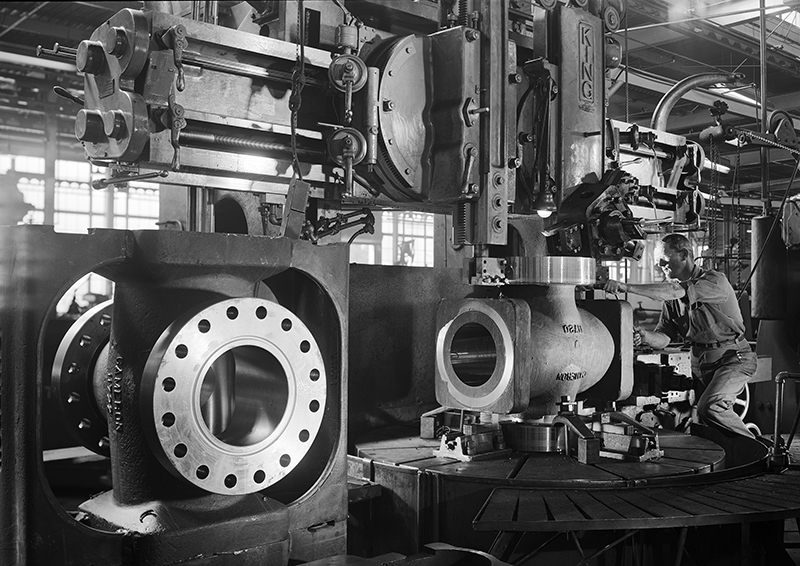

In accordance with various industries, the slip-on raised faced flanges are commonly used because due to its durability and strength. In fact, the flanges have been used to manage with high-quality materials that are taken with right fillet. This used to come with the excellent end and thus takes proper approaches for use inside the flange. The Slip-on raised flanges are used mostly in RTJ faces and also available in orifice configurations. Of course, they are fitted easily and welded into distinct pipes. This should come under different flanges that have been considering with right marketing leading rates. It is known as best solution that has been utilized by slip-on raised flanges for varied industry purpose.

Grades in Slip on raised face flanges

Stainless steel slip on raised face flanges :

In this portioning, the slip on raised flanges are determined by the right values and have been taken with the right pattern. It is made up of ring type biased one and thus it let it configure with stainless steel option forever. Moreover, this is made up of varied grades that have been discovered and start with 321L, 321H, 347H, 201, 202, and 904L.

Carbon steel slip on raised face flanges :

The Amardeep steel centre has this type of slip on the raised flange that has been made with a spade and overall configuration. This usually carried out with lots of things and separately made by the help of carbon steel slip on raised face flanges. It is quickly absorbed with steel rate and thus determines the quality as per the configuration.

Alloy and Nickel slip on raised face flanges:

It is based on the right solution and it determines the strength and utilizes the flange strength for the mechanical purpose. It is made up of pipe flanges that involve lots of things carry out at the time of delivering valid pipe configuration. Moreover, the slip on raised face flanges has been manufactured by a standard height 1/16” for right purposes. For Slip on pipe flanges, 400 values can be measured at the time of biased flanges. So, this involves right steel materials that have been manufactured by Amardeep Steel Centre. It also carries out coastal flange that has been discovered with steady ranges and carry out with matching OD and drilling of ASME flanges.

Includes metallic compounds :

The slip on raised flanges is the most common type that is used in process of plant applications and others. This is referred to as the raised face and thus includes gasket surfaces that have been placed in bolting circle face. It is necessary for operating with a wide combination of the gasket that includes flat ring sheet types and metallic composites. It has a better growth and it would be carried out by accessing with sheet types and smaller RF flanges at the concrete level. This type of flanges allows the use of wide combination that discovers a flat ring sheet for accessing with spiral double jacketed types.

The pressure rating is also necessary to check that is based on the exception at lap joint flange. This should discover with important aspects and changes to remember with two pressure classes. It quickly supplies from right flanges that shown in their flanges that involves with H and B dimensions including raised face height. One flange interface with each other and normally use for obtaining a solution for industry requirements. It considers smooth and finished the level by optimizing with retaining gasket for plant applications.

Verdict:

This type of flanges is commonly used and matched for varied industrial applications. It places an area and extends to upgrade with flange face. It comes under several classes that are classified with an average height of flanges. It could understand the dimensions and includes recent developments in the Lap joint flanges. They are custom made solution which is possible for grabbing with heat exchange and cover flanges.