Facts To Know About Niobium

Posted on October 27, 2020 at 10:05 AM

Niobium (Nb) is an uncommon metal, a momentary component, and the 33rd most regular component on the world's hull. Niobium is essential to present-day society since niobium composites are utilized habitually in both steel-based development and logical hardware, particularly gear intended to leave the earth. Amardeep steel Centre has the best range of Niobium sheets and Niobium plates.

Essential Facts

Niobium is contracted Nb and is component number 41 on the occasional table. It has a nuclear load of 92.90638 and a particular gravity of 8.57. Niobium has a dissolving purpose of 2750 K (2477°C or 4491°F), and a breaking point of 5017 K (4744°C or 8571°F). Niobium can have a valence of +2, +3, +4, or +5. Niobium is a delicate, shin, bendable metal, which stays strong at room temperature (20°C).

Discovery

In 1734, Connecticut Gov. John Winthrop the Younger found another mineral and named it Columbite. He sent it to the British Museum in London, where it stayed until 1801 when Charles Hatchett dissected it and found that the Columbite contained an obscure component. Hatchett couldn't segregate the component, yet named it columbium. After eight years, William Hyde Wollaston hypothesized that columbium was really the component of Tantalum. (This was a simple misstep to make since tantalum and niobium are fundamentally the same.)

Chemical Compounds

The two principle mixes produced using Niobium will be niobium nitride and niobium carbide. Niobium nitride is a blend of niobium and nitrogen and is an exacerbate that fills in as a superconductor at low temperatures. Niobium nitride is frequently blended in with other conductive metals, for example, aluminum, tin, and titanium, to make much more superconductive material. Niobium carbide is a blend of Niobium and carbon and is a hard material with high refractivity.

Functions

Niobium Carbide is utilized in high-quality steel compounds to expand the quality and opposition of the steel to warmth and consumption. Niobium Nitride, and superconductive wires produced using it, are regularly used to make superconductor magnets for use in MRI gear, mass spectrometers, and other logical applications. Niobium is now and again utilized as a defensive covering, now and then utilized in adornments, and at times utilized in the production of focal points.

Potential

Niobium's properties make it an appealing material for capacitors and may one day supplant tantalum. The superconductive magnets produced using Niobium have various promising possible uses and uses of niobium particularly in the field of energy proficiency. Force stockpiling gadgets and transformers could be made more compelling with niobium and take into account simpler transmission of electric force. Looking further into the future, electric engines that suddenly spike in demand for magnets or even attractive levitation gadgets may be conceivable, the blend of which may be considered a MagLev train. Amardeep Steel Centre offers the best niobium prices.

Few facts about Niobium

1. In 1801, English scientific expert Charles Hatchett examined an example of an obscure mineral from the assortment of the British Museum in London and verified that this mineral contained 'another earth'. He named this component 'columbium'.

2. In 1809, British scientific expert William Hyde Wollaston examined both columbium and tantalum mineral examples and asserted that they were a similar component. There was no question of this end-around then.

3. In 1844, Heinrich Rose had the option to recognize columbium from tantalum by watching contrasts in their valence states. He renamed columbium to 'niobium' after Niobe, the little girl of Tantalus.

4. The names 'columbium' and 'niobium' were both used to recognize the component until 1949 when the International Union of Pure and Applied Chemistry (IUPAC) authoritatively embraced 'niobium' as the name.

5. Noteworthy U.S. niobium mine creation has not been accounted for since 1959.

6. From 2014 to 2017, U.S. niobium import sources were: Brazil, 72%; Canada, 18%; Russia, 3%; Germany, 2%; and others, 5%.

7. In May 2018, the U.S. Division of the Interior, as a team with other presidential branch organizations, distributed a top-notch of 35 basic minerals (83 FR 23295), including niobium. This rundown was created to fill in as an underlying center, in accordance with Executive Order 13817, ''A Federal Strategy to Ensure Secure and Reliable Supplies of Critical Minerals" (82 FR 60835).

8. Brazil is the world's driving provider of niobium (around 90%); its significant stores happen in Late Cretaceous carbonatite buildings. These buildings were emplaced along profound shortcomings situated along the southwestern fringe of the old (Archean) São Francisco craton. The Araxá store is the biggest working store; it has in excess of 460 million metric huge loads of endured minerals with a mean evaluation of 2.48 percent Nb2O5.

9. The main maker of niobium outside of Brazil is the Niobec Mine in Quebec, Canada. This mine is the main working underground niobium mine on the planet. The Niobec Mine is facilitated by the Saint-Honoré carbonatite complex dated at 650 uber annum (Ma), which is secured by Paleozoic limestone and frigid stores.

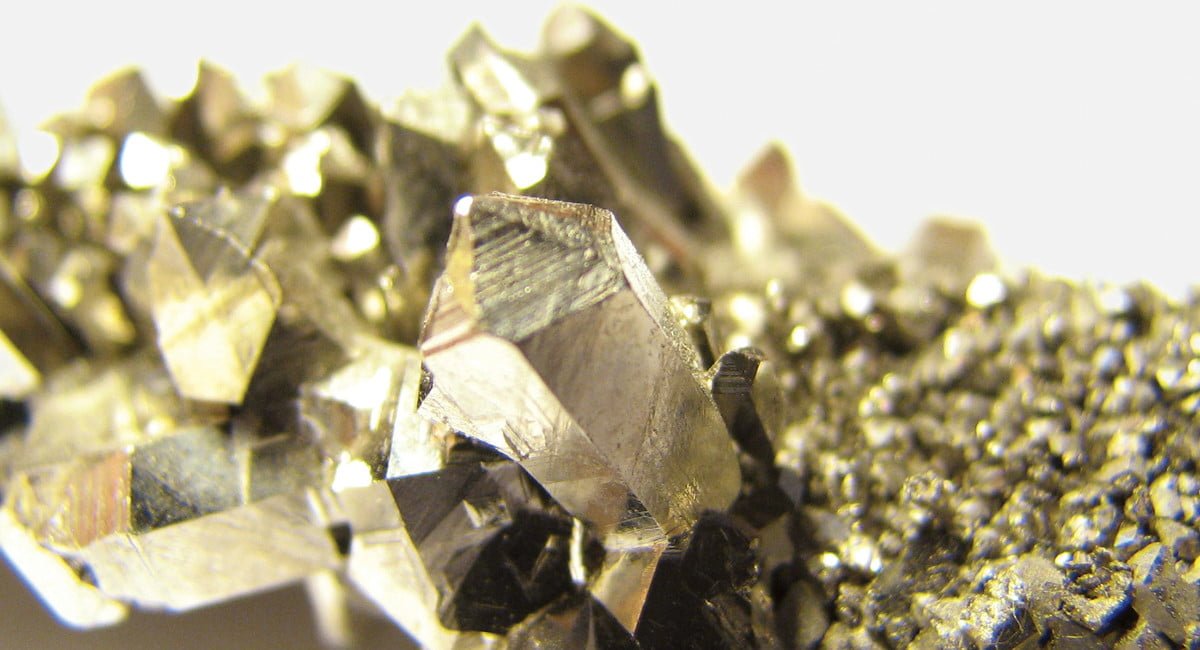

10. Niobium is a radiant, dark, flexible metal with a high liquefying point, generally low thickness, and superconductor properties.

11. Niobium doesn't happen normally as an unadulterated metal – it is essentially gotten from the mind-boggling oxide minerals of the pyrochlore gathering ((Na, Ca, Ce)2 (Nb, Ti, Ta)2 (O, OH, F)7 ) and has a normal bounty in the Earth's outside of 8.0 parts per million (ppm).

12. A combination of tantalum, niobium, hafnium, zirconium, and titanium has appeared to direct power with zero opposition, or superconductor, from surrounding pressure up to pressures like those that exist close to the focal point of the Earth. The material is an individual from another group of metal amalgams known as high-entropy compounds (HEAs), which are made out of arbitrary nuclear scale combinations of components from the square of "progress metals'' on the intermittent table.

13. Niobium is generally utilized for a body penetrating, and when gotten through an anodizing cycle brings about differing shades of adornments without the utilization of harmful inks or colors.

14. Niobium nickel-, cobalt-, and iron-based superalloys are basic for high-temperature applications in stream motors, gas turbines, rocket subassemblies, turbocharger frameworks, and burning hardware and discover popularity in the aeronautic trade. That, yet niobium composites are utilized in assembling superconducting magnets for clinical equipment, for example, attractive reverberation imaging (MRI) and atomic attractive reverberation (NMR) instruments. Niobium composites are contained in the superconducting magnets utilized in molecule quickening agents, for example, the Large Hadron Collider in Europe.

15.The steel business utilizes almost 80% of the world's delivered niobium to make high-quality preparations. Niobium, a grain purifier, and precipitation hardener will improve the prepared mechanical quality, durability, high-temperature quality, and consumption obstruction for use in pipelines, transportation, vehicle and truck bodies, device preparations, ships bodies, railroad tracks, compositional and auxiliary applications.