Advantages of Buying Steel from India

by Vidhi Gada

Posted on January 16, 2022 at 4:20 PM

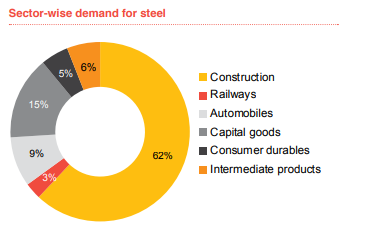

As India's economy continues to grow, the demand for steel has risen almost exponentially. Several Indian suppliers are working to increase their production efficiency and quality of steel. One of the major industries that India is involved in is the steel industry. This article talks about some of the reasons why you should buy steel from Indian companies and some of the benefits. Steel, as a key industry, is a long-distance racehorse that drives India's overall development. Automobiles, infrastructure, defence, and research are among the main areas driving the rising need for steel production in India, both for internal consumption and export. India has a favourable geographic position, which is rich in iron ore and employs low-cost labour. Furthermore, the Indian government has eased limitations on steel-related business and activities. The tremendous performance of the steel sector is reflected in India's current rating in Ease of Doing Business, which has risen from 100 in 2018 to 77 in 2019.

The Indian steel industry now has a capacity of 122 million tonnes (2015-16), whereas the global steel production capacity is 1630 million tonnes. By 2030, India wants to increase its capacity to 300 million tonnes. Today, the steel sector contributes roughly 2% of our country's GDP and employs about 5 lakh people directly and another 20 lakh indirectly.

Advantages of Buying Steel From India

Global Advantage

The Indian steel industry has had economic relations with other nations since its start. The steel factories at Durgapur, Rourkela, and Bhilai were built in connection with the United Kingdom, Germany, and Russia, respectively. Over the years, Indian firms have signed a number of Memorandums of Understanding (MOUs) with other nations, particularly in the field of technology, in order to develop joint ventures (JVs) in the steel industry.

Constant Government Support

The Indian government has long backed the steel sector, and in 2017 they announced the National Steel Policy, which forecasts the Indian steel industry's development trajectory through 2030–31. According to the Joint Plant Committee, India produced 110.9 million tonnes of crude steel in 2018–19.To achieve 255 million tonnes of crude steel output by 2030–31, production must increase at a CAGR of 7.2 percent. Given that crude steel output increased by 7.6% in 2018–19, this is a simple task. As a result, the government's development potential, as outlined in the National Steel Policy of 2017, is in line with the industry's growth trajectory.

Strict Quality Control

The certification, testing, and retesting of raw materials is a must in Indian enterprises and facilities. If you're planning a steel project, you should think about including India into your global supply chain. In the long term, such critical sourcing will pay dividends.

Labour Cost

Talking about the labor pool, we work as a practical choice for China because of its cheaper labor cost. A report says that India’s continually manufacturing labor cost averaged 92 cents compared to $3.52 in China. India’s steel manufacturing is viable and thriving at present. Indian labor never goes out of business due to its excess supply.

Conclusion

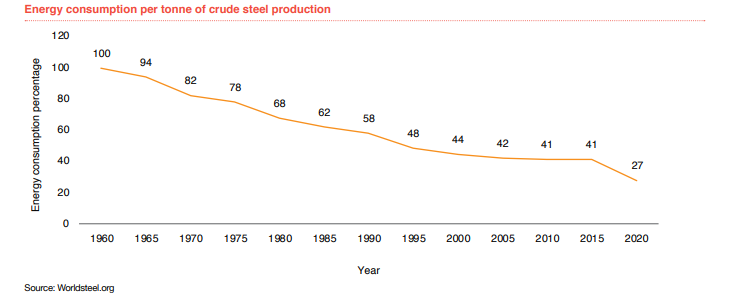

Steel prices in India are likely to be the lowest in the world. Due to these characteristics, the Indian steel industry has emerged as the most lucrative and competitive steel sector in the world. In the future, India may overtake China as the world's biggest steel manufacturer. It has always strived to upgrade traditional facilities to greater energy efficiency levels and to modernise them on a constant basis. Despite the fact that the predicted demand seems to be favourable for the Indian steel industry, investors and capitalists are keeping their fingers crossed owing to the uncertainty in demand caused by the US-China trade war and shifting nickel prices globally.