Why is Grade 304 known as the workhorse of the Stainless Steel Industry?

Posted on June 11, 2020 at 3:05 PM

It's not astonishing that grade 304 tempered steel is one of the most well known assessments. In any case it is clearly not in light of the fact that grade 304 was one of the chief grades developed that it continues instructing the market today. There has been broad headway consistently, and we as of now have despite a wide extent of austenitic levels of which 304 is just one - a wide extent of ferritic levels, 200 game plan levels, Duplex, Superduplex, and Lean Duplex assessments. Each of these has express properties and has been made for explicit applications, or in any event, attempting to avoid using exorbitant alloying components. It contains a raised degree of nickel and chromium. Since Nickel weighed in at some place in the scope of 8 and 10.5%. What's more the proportion of chromium goes from 18 to 20% by weight. SS 304 other alloying segments fuse silicon and manganese with iron, as containing the remaining manufactured structure. Chromium and nickel give Stainless Steel 304 its high utilization restriction.

Standard applications for SS 304 include:

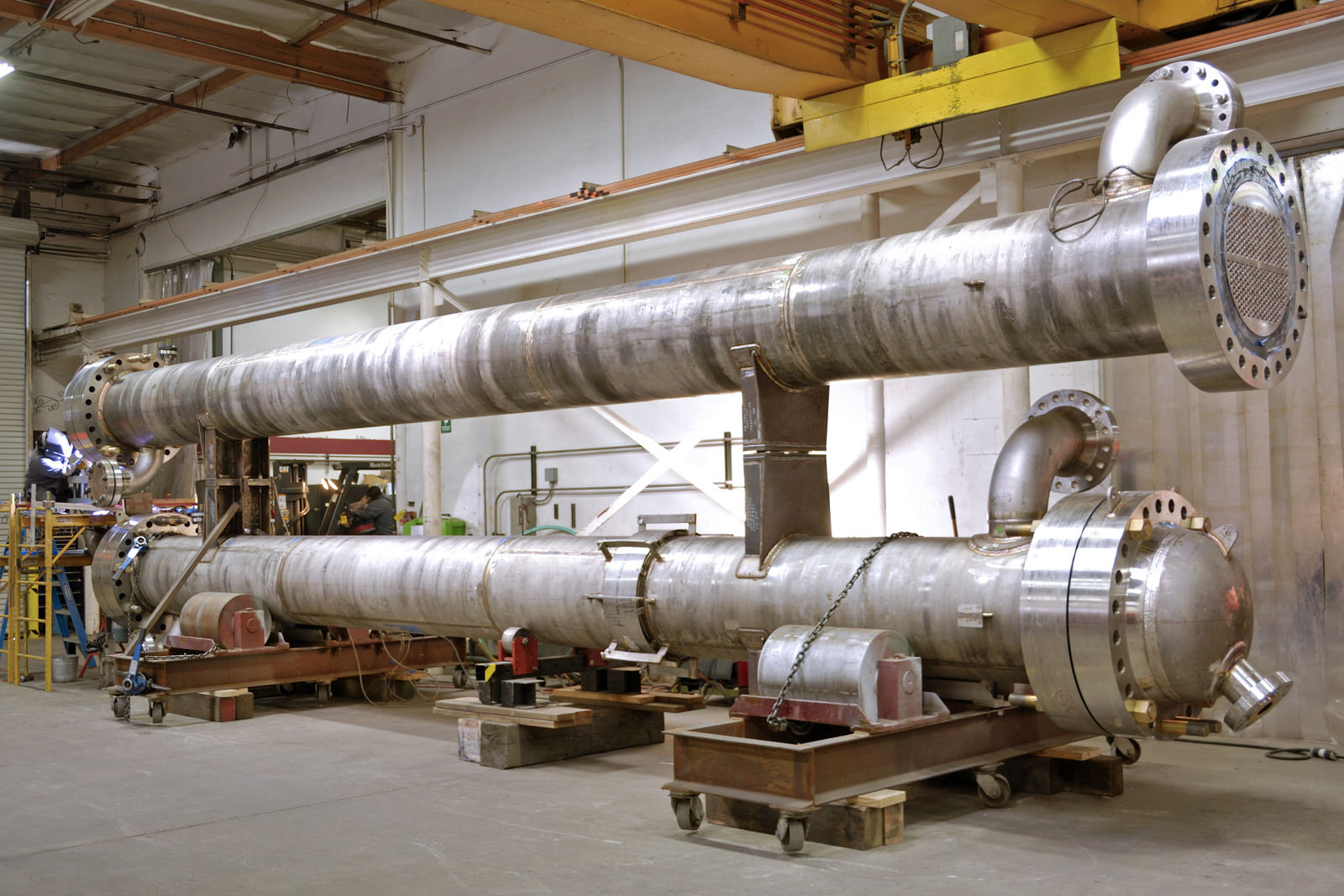

- Heat exchangers

- Fasteners

- Piping

- Making structures in the environment that would wear down carbon steel

- Commercial food processing equipment

- Household Appliances

Characteristics Of Grade 304

Strengths

- The grade has phenomenal framing qualities. It very well may be drawn with no transitional warmth relaxing procedure.

- It has great maintenance of properties particularly durability at cryogenic temperatures.

- No post weld strengthening is required to reestablish the erosion opposition in a large portion of the cases. The low carbon 304L grade can be utilized where carbide precipitation should be kept low.

- The grade offers great protection from a large portion of the oxidizing acids and is anything but difficult to clean and sanitize.

Weakness

- Machinability of SS 304 is second rate compared to carbon prepared. It is promptly machined given more slow speeds and high feed rates with cutting liquids are utilized.

- 304 is powerless to stretch consumption splitting. It has mediocre consumption in chloride and saline conditions. Chloride particles cause restricted pitting consumption which bargains the basic unbending nature of the item.

Grade 304 holds its fame since it is, moderately, a 'modest' choice. It contains a considerable amount of nickel which, as we as a whole know, can turn into an over the top expensive fixing in reality, particularly when a time of restocking follows a time of destocking, when costs in this way begin to rise. All in all, on the off chance that it isn't for authentic reasons that grade 304 is so famous, and not on the grounds that it doesn't contain "costly" alloying components, for example, nickel, since it does, for what reason does it remain the workhorse of the business? The appropriate response is maybe right off the bat that grade 304 contains an extremely tolerable measure of chrome (around 18%), and it is, obviously, the chrome that makes it so consumption safe. Why at that point include nickel, which just adds to the expense? Since nickel settles the austenitic structure, which implies that the steel is both intense and malleable. What amount of nickel ought to be included? Clearly, the base expected to settle the austenitic structure – so about 8%. What's more, there we have it – grade 18/8 (18% Cr, 8% Ni) or indeed, grade 304. The outcome is a grade that is profoundly consumption safe in a wide scope of uses, has great formability, and great weldability, however doesn't contain such a great amount of nickel as to make it restrictively costly, when that measure of nickel isn't required for the specific application. It is the mix of these properties which clarifies why 304 stays one of the most generally utilized grades. The specific mix of properties implies that it is appropriate, at a truly sensible expense, for use in the most differed of utilizations going from industry (substance, pharmaceutical, groceries, refreshment, blending, maturation), to development, dissemination (counters and so on), down to your own one of a kind kitchen and cutlery.

Versatile grade

The adaptability and execution of grade 304 has been demonstrated over numerous long stretches of utilization, yet it is inappropriate to state that it is a "sure thing", or "I am certain 304 will be fine". You could state it is somewhat similar to purchasing a vehicle. You don't accept an Audi R8, as pleasant as it sounds, and as quick as it goes, if what you need is a Renault Clio that gets you to the corner shop similarly as fast, and at fundamentally lower cost. However, nor do you purchase a modest runabout, which is more than prone to separate most of the way to the air terminal, in the event that you have a plane to get. This is the reason you ought to consistently converse with the specialists who will propose the grade you require for your specific application, at the most sensible expense, and assist you with abstaining from making what could be an exorbitant error in the more drawn out term. With that proviso, spotless grade 304 is the workhorse of the hardened steel industry. It has been so since it was first evolved, and looks set to keep being so for a long time to come. At Stainless Band we generally have a lot of grade 304 loops in the distribution center which can be cut at short notification into the exact width of strip required and with the necessary preparation and finish.