ASME B16.5 is a widely used standard that defines the dimensions, tolerances, materials, and

testing requirements for flanges used in piping systems. Flanges are used to connect pipes, valves, and other

components in a piping system, and they come in a variety of sizes and shapes to accommodate different

applications.

ASME B16.5 flanges are designed to withstand high pressure and temperature conditions in various industries,

such as oil and gas, chemical, and power generation. The standard covers a range of materials, including

carbon

steel, stainless steel, and alloy steel, and it specifies different pressure classes ranging from 150 to 2500.

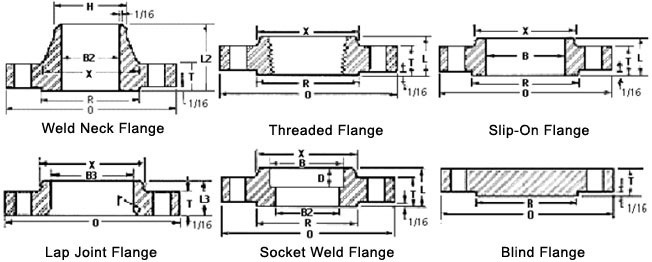

One of the key advantages of ASME B16.5 flanges is their versatility. They can be used to connect pipes of

different sizes and materials, and they come in a range of shapes, such as slip-on, weld-neck, threaded, and

blind. This flexibility makes ASME B16.5 flanges suitable for a wide range of applications, from low-pressure

to

high-pressure systems.

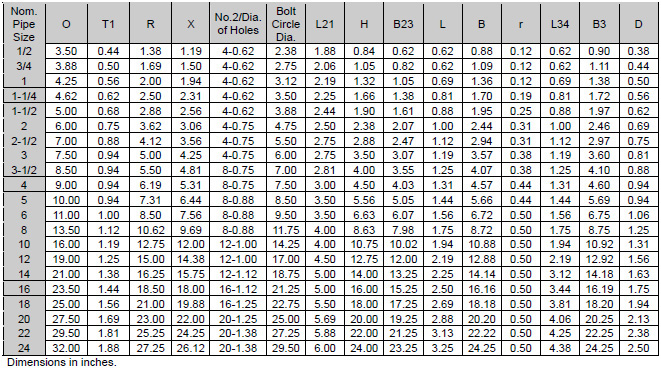

ASME B16.5 flanges also have a high level of dimensional accuracy, which ensures that the flanges fit together

seamlessly and prevent leaks in the piping system. The standard specifies tolerances for various dimensions,

such as the outer diameter, bolt circle diameter, and thickness, to ensure that the flanges meet the required

specifications.

In addition, ASME B16.5 flanges undergo rigorous testing to ensure their quality and safety. The standard

specifies various non-destructive testing methods, such as visual inspection, magnetic particle testing, and

radiographic testing, to detect any defects or imperfections in the flanges.

Overall, ASME B16.5 flanges are an important component in piping systems, and their use ensures that pipes,

valves, and other components are connected securely and safely. They are available in a wide range of materials,

shapes, and pressure classes, and their high level of dimensional accuracy and rigorous testing make them a

reliable and durable choice for a variety of applications.

| ANSI B16.5 Flange Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

|---|---|

| ASME B16.5 /ANSI B16.5 Flange Size Chart | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

| ANSI B16.5 Flange Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 ANSI B16.5 Flange |

| ANSI B16.5 Flange Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS ANSI B16.5 Flange |

| UNI | 6Bar 10Bar 16Bar 25Bar 40Bar ANSI B16.5 Flange |

| JIS | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K ANSI B16.5 Flange |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized ANSI B16.5 Flange |

| EN | 6Bar 10Bar 16Bar 25Bar 40Bar ANSI B16.5 Flange |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Most common types of ANSI B16.5 Flange | Forged / Threaded / Screwed / Plate |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Production technique |

|

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Special design |

As per your drawing AS, ANSI, BS, DIN and JIS |

| Origin | Indian / West Europe / Japan / USA / Korean |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| ANSI B16.5 Flange Uses & application |

|

| Manufacturer of |

ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc.

|

| Export to | Saudi Arabia, Peru, Egypt, Indonesia, Brazil, Spain, USA, Canada, Ukraine, Singapore, Thailand, Oman, Ireland, Korea, Iran, India, Dubai |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

| Stainless Steel ANSI B16.5 Flange | ASTM/ASME A/SA182 F304, F304L, F316, F316L, ASTM/ASME A/SA351 CF8, CF3, CF8M, CF3M, DIN 1.4301, DIN 1.4306, DIN 1.4401, DIN 1.4404, DIN 1.4308, DIN 1.4408, DIN 1.4306, DIN 1.4409 |

| Carbon Steel ANSI B16.5 Flange | ASTM/ASME A/SA105 A/SA105N & A/SA216-WCB, DIN 1.0402, DIN 1.0460, DIN 1.0619, Die Steel, ASTM A105 / ASME SA105, A105N, ASTM A350 LF2 / ASME SA350, High Yield CS ASTM A694 / A694 (F52 F56 F60 F65 F70 F80) |

| Titanium ANSI B16.5 Flange | ASTM B381 / ASME SB381, Titanium Gr. 1, Titanium Gr. 2, Titanium Gr. 4, Titanium Gr. 5, Titanium Gr.

7 ASTM R50250/GR.1 | R50400/GR.2 | R50550/GR.3 | R50700/GR.4 | GR.6 |R52400/GR.7 | R53400/GR.12 | R56320/GR.9 |R56400/GR.5 |

| Alloy Steel ANSI B16.5 Flange | ASTM A182 / ASME SA182 F5, F9, F11, F12, F22, F91 |

| Copper Nickel ANSI B16.5 Flange | ASTM / ASME SB 61 / 62 / 151 / 152, Copper Nickel 90/10 (C70600 ), Cupro Nickel 70/30 (C71500), UNS C71640 |

| Copper ANSI B16.5 Flange | T1, T2, C10100, C10200, C10300, C10400, C10500, C10700, C10800, C10910,C10920, TP1, TP2, C10930, C11000, C11300, C11400, C11500, C11600, C12000,C12200, C12300, TU1, TU2, C12500, C14200, C14420, C14500, C14510, C14520, C14530, C17200, C19200, C21000, C23000, C26000, C27000, C27400, C28000, C33000, C33200, C37000, C44300, C44400, C44500, C60800, C63020, C68700, C70400, C70600, C70620, C71000, C71500, C71520, C71640, etc |

| Inconel ANSI B16.5 Flange | ASTM B564 / ASME SB564, Inconel 600, 601, 625, 718, 783, 690, x750 ANSI B16.5 Flange |

| Brass ANSI B16.5 Flange | 3602 / 2604 / H59 / H62 / etc. |

| Monel ANSI B16.5 Flange | ASTM B564 / ASME SB564, Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500) |

| Hastelloy ANSI B16.5 Flange | ASTM B564 / ASME SB564, Hastelloy C276 (UNS N10276), C22 (UNS N06022), C4, C2000, B2, B3, X Flanges |

| Aluminium ANSI B16.5 Flange | 5052 /6061/ 6063 / 2017 / 7075 / etc. |

| Alloy 20 ANSI B16.5 Flange | ASTM B462 / ASME SB462, Carpenter® 20 Alloy, Alloy 20Cb-3 |

| Duplex ANSI B16.5 Flange | S31803 / S32205 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Nickel ANSI B16.5 Flange | ASTM B564 / ASME SB564, Nickel 200, Nickel 201, Nickel 205, Nickel 205LC |

| Incoloy ANSI B16.5 Flange | ASTM B564 / ASME SB564, Incoloy 800, 800H, 800HT (UNS N08800), 825 (UNS N08825), 925 Flanges |

| Super Duplex ANSI B16.5 Flange | S32750 / S32760 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Other ANSI B16.5 Flange material | Tin bronze, Alumunum bronze, Lead bronze |

| Nimonic ANSI B16.5 Flange | Nimonic 75, Nimonic 80A, Nimonic 90 |

| 254 Smo ANSI B16.5 Flange | ASTM A182 / ASME SA182, SMO 254/6Mo, UNS S31254, DIN 1.4547 |

ASME B16.5 Class 150 Flange Dimensions

|

Nominal Size

|

Outside Diameter

(OD) |

Min. Thickness

(T) |

RF Dia.

(R) |

No. of Bolt Holes

|

Diameter of Holes

|

Bolt Circle

(BC) |

SO Bore ID

(SB) |

WN Bore ID

(WB) |

Dia. Hub Base

(HB) |

Dia. of Hub Top

(HT) |

SO LTH

(SL) |

WN LTH

(WL) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

1⁄2

|

3.50

|

0.38

|

1.38

|

4

|

0.62

|

2.38

|

0.88

|

0.62

|

1.19

|

0.84

|

0.56

|

1.81

|

|

3⁄4

|

3.88

|

0.44

|

1.69

|

4

|

0.62

|

2.75

|

1.09

|

0.82

|

1.50

|

1.05

|

0.56

|

2.00

|

|

1

|

4.25

|

0.50

|

2.00

|

4

|

0.62

|

3.12

|

1.36

|

1.05

|

1.94

|

1.32

|

0.62

|

2.12

|

|

11⁄4

|

4.62

|

0.56

|

2.50

|

4

|

0.62

|

3.50

|

1.70

|

1.38

|

2.31

|

1.66

|

0.75

|

2.19

|

|

11⁄2

|

5.00

|

0.62

|

2.88

|

4

|

0.62

|

3.88

|

1.95

|

1.61

|

2.56

|

1.90

|

0.81

|

2.38

|

|

2

|

6.00

|

0.69

|

3.62

|

4

|

0.75

|

4.75

|

2.44

|

2.07

|

3.06

|

2.38

|

0.94

|

2.44

|

|

21⁄2

|

7.00

|

0.81

|

4.12

|

4

|

0.75

|

5.50

|

2.94

|

2.47

|

3.56

|

2.88

|

1.06

|

2.69

|

|

3

|

7.50

|

0.88

|

5.00

|

4

|

0.75

|

6.00

|

3.57

|

3.07

|

4.25

|

3.50

|

1.12

|

2.69

|

|

31⁄2

|

8.50

|

0.88

|

5.50

|

8

|

0.75

|

7.00

|

4.07

|

3.55

|

4.81

|

4.00

|

1.19

|

2.75

|

|

4

|

9.00

|

0.88

|

6.19

|

8

|

0.75

|

7.50

|

4.57

|

4.03

|

5.31

|

4.50

|

1.25

|

2.94

|

|

5

|

10.00

|

0.88

|

7.31

|

8

|

0.88

|

8.50

|

5.66

|

5.05

|

6.44

|

5.56

|

1.38

|

3.44

|

|

6

|

11.00

|

0.94

|

8.50

|

8

|

0.88

|

9.50

|

6.72

|

6.07

|

7.56

|

6.63

|

1.50

|

3.44

|

|

8

|

13.50

|

1.06

|

10.62

|

8

|

0.88

|

11.75

|

8.72

|

7.98

|

9.69

|

8.63

|

1.69

|

3.94

|

|

10

|

16.00

|

1.12

|

12.75

|

12

|

1.00

|

14.25

|

10.88

|

10.02

|

12.00

|

10.75

|

1.88

|

3.94

|

|

12

|

19.00

|

1.19

|

15.00

|

12

|

1.00

|

17.00

|

12.88

|

12.00

|

14.38

|

12.75

|

2.12

|

4.44

|

|

14

|

21.00

|

1.31

|

16.25

|

12

|

1.12

|

18.75

|

14.14

|

13.25

|

15.75

|

14.00

|

2.19

|

4.94

|

|

16

|

23.50

|

1.38

|

18.50

|

16

|

1.12

|

21.25

|

16.16

|

15.25

|

18.00

|

16.00

|

2.44

|

4.94

|

|

18

|

25.00

|

1.50

|

21.00

|

16

|

1.25

|

22.75

|

18.18

|

17.25

|

19.88

|

18.00

|

2.62

|

5.44

|

|

20

|

27.50

|

1.62

|

23.00

|

20

|

1.25

|

25.00

|

20.20

|

19.25

|

22.00

|

20.00

|

2.81

|

5.62

|

|

22

|

29.50

|

1.75

|

25.25

|

20

|

1.38

|

27.25

|

22.22

|

21.25

|

24.25

|

22.00

|

3.07

|

5.82

|

|

24

|

32.00

|

1.81

|

27.25

|

20

|

1.38

|

29.50

|

24.25

|

23.25

|

26.12

|

24.00

|

3.19

|

5.94

|

|

Nominal Size

|

Outside Diameter

(OD) |

Min. Thickness

(T) |

RF Dia.

(R) |

No. of Bolt Holes

|

Diameter of Holes

|

Bolt Circle

(BC) |

SO Bore ID

(SB) |

WN Bore ID

(WB) |

Dia. Hub Base

(HB) |

Dia. Hub Top

(HT) |

SO LTH

(SL) |

WN LTH

(WL) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

1⁄2

|

3.75

|

0.50

|

1.38

|

4

|

0.63

|

2.62

|

0.88

|

0.62

|

1.50

|

0.84

|

0.81

|

2.00

|

|

3⁄4

|

4.62

|

0.56

|

1.69

|

4

|

0.75

|

3.25

|

1.09

|

0.82

|

1.88

|

1.05

|

0.94

|

2.19

|

|

1

|

4.88

|

0.62

|

2.00

|

4

|

0.75

|

3.50

|

1.36

|

1.05

|

2.12

|

1.32

|

1.00

|

2.38

|

|

11⁄4

|

5.25

|

0.69

|

2.50

|

4

|

0.75

|

3.88

|

1.70

|

1.38

|

2.50

|

1.66

|

1.00

|

2.50

|

|

11⁄2

|

6.12

|

0.75

|

2.88

|

4

|

0.88

|

4.50

|

1.95

|

1.61

|

2.75

|

1.90

|

1.13

|

2.63

|

|

2

|

6.50

|

0.81

|

3.62

|

8

|

0.75

|

5.00

|

2.44

|

2.07

|

3.31

|

2.38

|

1.25

|

2.69

|

|

21⁄2

|

7.50

|

0.94

|

4.12

|

8

|

0.88

|

5.88

|

2.94

|

2.47

|

3.94

|

2.88

|

1.44

|

2.94

|

|

3

|

8.25

|

1.06

|

5.00

|

8

|

0.88

|

6.62

|

3.57

|

3.07

|

4.62

|

3.50

|

1.63

|

3.06

|

|

31⁄2

|

9.00

|

1.12

|

5.50

|

8

|

0.88

|

7.25

|

4.07

|

3.55

|

5.25

|

4.00

|

1.69

|

3.13

|

|

4

|

10.00

|

1.19

|

6.19

|

8

|

0.88

|

7.88

|

4.57

|

4.03

|

5.75

|

4.50

|

1.82

|

3.32

|

|

5

|

11.00

|

1.31

|

7.31

|

8

|

0.88

|

9.25

|

5.66

|

5.05

|

7.00

|

5.56

|

1.94

|

3.82

|

|

6

|

12.50

|

1.38

|

8.50

|

12

|

0.88

|

10.62

|

6.72

|

6.07

|

8.12

|

6.63

|

2.00

|

3.82

|

|

8

|

15.00

|

1.56

|

10.62

|

12

|

1.00

|

13.00

|

8.72

|

7.98

|

10.25

|

8.63

|

2.38

|

4.32

|

|

10

|

17.50

|

1.81

|

12.75

|

16

|

1.12

|

15.25

|

10.88

|

10.02

|

12.62

|

10.75

|

2.56

|

4.56

|

|

12

|

20.50

|

1.94

|

15.00

|

16

|

1.25

|

17.75

|

12.88

|

12.00

|

14.75

|

12.75

|

2.82

|

5.06

|

|

14

|

23.00

|

2.06

|

16.25

|

20

|

1.25

|

20.25

|

14.14

|

13.25

|

16.75

|

14.00

|

2.94

|

5.56

|

|

16

|

25.50

|

2.19

|

18.50

|

20

|

1.38

|

22.50

|

16.16

|

15.25

|

19.00

|

16.00

|

3.19

|

5.69

|

|

18

|

28.00

|

2.31

|

21.00

|

24

|

1.38

|

24.75

|

18.18

|

17.25

|

21.00

|

18.00

|

3.44

|

6.19

|

|

20

|

30.50

|

2.44

|

23.12

|

24

|

1.38

|

27.00

|

20.20

|

19.25

|

23.12

|

20.00

|

3.69

|

6.32

|

|

22

|

33.00

|

2.57

|

25.25

|

24

|

1.63

|

29.25

|

22.22

|

21.25

|

25.25

|

22.00

|

3.93

|

6.43

|

|

24

|

36.00

|

2.69

|

27.62

|

24

|

1.63

|

32.00

|

24.25

|

23.25

|

27.62

|

24.00

|

4.13

|

6.56

|

|

Nominal Size

|

Outside Diameter

(OD) |

Min. Thickness

(T) |

RF Dia.

(R) |

No. of Bolt Holes

|

Diameter of Holes

|

Bolt Circle

(BC) |

SO Bore ID

(SB) |

Dia. Hub Base

(HB) |

Dia. Hub Top

(HT) |

SO LTH

(SL) |

WN LTH

(WL) |

* WN Bore ID

(WB) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

1⁄2

|

3.75

|

0.56

|

1.38

|

4

|

0.63

|

2.62

|

0.88

|

1.5

|

0.84

|

0.88

|

2.06

|

*

|

|

3⁄4

|

4.62

|

0.62

|

1.69

|

4

|

0.75

|

3.25

|

1.09

|

1.88

|

1.05

|

1.00

|

2.25

|

*

|

|

1

|

4.88

|

0.69

|

2.00

|

4

|

0.75

|

3.50

|

1.36

|

2.12

|

1.32

|

1.06

|

2.44

|

*

|

|

11⁄4

|

5.25

|

0.81

|

2.50

|

4

|

0.75

|

3.88

|

1.70

|

2.50

|

1.66

|

1.12

|

2.62

|

*

|

|

11⁄2

|

6.12

|

0.88

|

2.88

|

4

|

0.88

|

4.50

|

1.95

|

2.75

|

1.90

|

1.25

|

2.75

|

*

|

|

2

|

6.50

|

1.00

|

3.62

|

8

|

0.75

|

5.00

|

2.44

|

3.31

|

2.38

|

1.44

|

2.88

|

*

|

|

21⁄2

|

7.50

|

1.12

|

4.12

|

8

|

0.88

|

5.88

|

2.94

|

3.94

|

2.88

|

1.62

|

3.12

|

*

|

|

3

|

8.25

|

1.25

|

5.00

|

8

|

0.88

|

6.62

|

3.57

|

4.62

|

3.50

|

1.81

|

3.25

|

*

|

|

31⁄2

|

9.00

|

1.38

|

5.50

|

8

|

1.00

|

7.25

|

4.07

|

5.25

|

4.00

|

1.94

|

3.38

|

*

|

|

4

|

10.00

|

1.38

|

6.19

|

8

|

1.00

|

7.88

|

4.57

|

5.75

|

4.50

|

2.00

|

3.50

|

*

|

|

5

|

11.00

|

1.50

|

7.31

|

8

|

1.00

|

9.25

|

5.66

|

7.00

|

5.56

|

2.12

|

4.00

|

*

|

|

6

|

12.50

|

1.62

|

8.50

|

12

|

1.00

|

10.62

|

6.72

|

8.12

|

6.63

|

2.25

|

4.06

|

*

|

|

8

|

15.00

|

1.88

|

10.62

|

12

|

1.12

|

13.00

|

8.72

|

10.25

|

8.63

|

2.69

|

4.62

|

*

|

|

10

|

17.50

|

2.12

|

12.75

|

16

|

1.25

|

15.25

|

10.88

|

12.62

|

10.75

|

2.88

|

4.88

|

*

|

|

12

|

20.50

|

2.25

|

15.00

|

16

|

1.38

|

17.75

|

12.88

|

14.75

|

12.75

|

3.12

|

5.38

|

*

|

|

14

|

23.00

|

2.38

|

16.25

|

20

|

1.38

|

20.25

|

14.14

|

16.75

|

14.00

|

3.31

|

5.88

|

*

|

|

16

|

25.50

|

2.50

|

18.50

|

20

|

1.50

|

22.50

|

16.16

|

19.00

|

16.00

|

3.69

|

6.00

|

*

|

|

18

|

28.00

|

2.62

|

21.00

|

24

|

1.50

|

24.75

|

18.18

|

21.00

|

18.00

|

3.88

|

6.50

|

*

|

|

20

|

30.50

|

2.75

|

23.12

|

24

|

1.62

|

27.00

|

20.20

|

23.12

|

20.00

|

4.00

|

6.62

|

*

|

|

22

|

33.00

|

2.88

|

25.25

|

24

|

1.75

|

29.25

|

22.22

|

25.25

|

22.00

|

4.25

|

6.75

|

*

|

|

24

|

36.00

|

3.00

|

27.25

|

24

|

1.88

|

32.00

|

24.25

|

27.62

|

24.00

|

4.50

|

6.88

|

*

|

|

Nominal Size

|

Outside Diameter

(OD) |

Min. Thickness

(T) |

RF Dia.

(R) |

No. of Bolt Holes

|

Diameter of Holes

|

Bolt Circle

(BC) |

SO Bore ID

(SB) |

Dia. Hub Base

(HB) |

Dia. Hub Top

(HT) |

SO LTH

(SL) |

WN LTH

(WL) |

* WN Bore ID

(WB) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

1⁄2

|

3.75

|

0.56

|

1.38

|

4

|

0.63

|

2.62

|

0.88

|

1.50

|

0.84

|

0.88

|

2.06

|

*

|

|

3⁄4

|

4.62

|

0.62

|

1.69

|

4

|

0.75

|

3.25

|

1.09

|

1.88

|

1.05

|

1.00

|

2.25

|

*

|

|

1

|

4.88

|

0.69

|

2.00

|

4

|

0.75

|

3.50

|

1.36

|

2.12

|

1.32

|

1.06

|

2.44

|

*

|

|

11⁄4

|

5.25

|

0.81

|

2.50

|

4

|

0.75

|

3.88

|

1.70

|

2.50

|

1.66

|

1.12

|

2.62

|

*

|

|

11⁄2

|

6.12

|

0.88

|

2.88

|

4

|

0.88

|

4.50

|

1.95

|

2.75

|

1.90

|

1.25

|

2.75

|

*

|

|

2

|

6.50

|

1.00

|

3.62

|

8

|

0.75

|

5.00

|

2.44

|

3.31

|

2.38

|

1.44

|

2.88

|

*

|

|

21⁄2

|

7.50

|

1.12

|

4.12

|

8

|

0.88

|

5.88

|

2.94

|

3.94

|

2.88

|

1.62

|

3.12

|

*

|

|

3

|

8.25

|

1.25

|

5.00

|

8

|

0.88

|

6.62

|

3.57

|

4.62

|

3.50

|

1.81

|

3.25

|

*

|

|

31⁄2

|

9.00

|

1.38

|

5.50

|

8

|

1.00

|

7.25

|

4.07

|

5.25

|

4.00

|

1.94

|

3.38

|

*

|

|

4

|

10.75

|

1.50

|

6.19

|

8

|

1.00

|

8.50

|

4.57

|

6.00

|

4.50

|

2.12

|

4.00

|

*

|

|

5

|

13.00

|

1.75

|

7.31

|

8

|

1.12

|

10.50

|

5.66

|

7.44

|

5.56

|

2.38

|

4.50

|

*

|

|

6

|

14.00

|

1.88

|

8.50

|

12

|

1.12

|

11.50

|

6.72

|

8.75

|

6.63

|

2.62

|

4.62

|

*

|

|

8

|

16.50

|

2.19

|

10.62

|

12

|

1.25

|

13.75

|

8.72

|

10.75

|

8.63

|

3.00

|

5.25

|

*

|

|

10

|

20.00

|

2.50

|

12.75

|

16

|

1.38

|

17.00

|

10.88

|

13.50

|

10.75

|

3.38

|

6.00

|

*

|

|

12

|

22.00

|

2.62

|

15.00

|

20

|

1.38

|

19.25

|

12.88

|

15.75

|

12.75

|

3.62

|

6.12

|

*

|

|

14

|

23.75

|

2.75

|

16.25

|

20

|

1.50

|

20.75

|

14.14

|

17.00

|

14.00

|

3.69

|

6.50

|

*

|

|

16

|

27.00

|

3.00

|

18.50

|

20

|

1.63

|

23.75

|

16.16

|

19.50

|

16.00

|

4.19

|

7.00

|

*

|

|

18

|

29.25

|

3.25

|

21.00

|

20

|

1.75

|

25.75

|

18.18

|

21.50

|

18.00

|

4.62

|

7.25

|

*

|

|

20

|

32.00

|

3.50

|

23.00

|

24

|

1.75

|

28.50

|

20.20

|

24.00

|

20.00

|

5.00

|

7.50

|

*

|

|

22

|

34.25

|

3.75

|

25.25

|

24

|

1.88

|

30.63

|

22.22

|

26.25

|

22.00

|

5.25

|

7.75

|

*

|

|

24

|

37.00

|

4.00

|

27.25

|

24

|

2.00

|

33.00

|

24.25

|

28.25

|

24.00

|

5.50

|

8.00

|

*

|

|

Nominal Size

|

Outside Diameter

(OD) |

Min. Thickness

(T) |

RF Dia.

(R) |

No. of Bolt Holes

|

Diameter of Holes

|

Bolt Circle

(BC) |

SO Bore ID

(SB) |

* WN Bore ID

(WB) |

Dia. Hub Base

(HB) |

Dia. Hub Top

(HT) |

SO LTH

(SL) |

WN LTH

(WL) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

3

|

9.50

|

1.50

|

5.00

|

8

|

1.00

|

7.50

|

3.57

|

*

|

5.00

|

3.50

|

2.12

|

4.00

|

|

4

|

11.50

|

1.75

|

6.19

|

8

|

1.25

|

9.25

|

4.57

|

*

|

6.25

|

4.50

|

2.75

|

4.50

|

|

5

|

13.75

|

2.00

|

7.31

|

8

|

1.38

|

11.00

|

5.66

|

*

|

7.50

|

5.56

|

3.12

|

5.00

|

|

6

|

15.00

|

2.19

|

8.50

|

12

|

1.25

|

12.50

|

6.72

|

*

|

9.25

|

6.63

|

3.38

|

5.50

|

|

8

|

18.50

|

2.50

|

10.63

|

12

|

1.50

|

15.50

|

8.72

|

*

|

11.75

|

8.63

|

4.00

|

6.38

|

|

10

|

21.50

|

2.75

|

12.75

|

16

|

1.50

|

18.50

|

10.88

|

*

|

14.50

|

10.75

|

4.25

|

7.25

|

|

12

|

24.00

|

3.12

|

15.00

|

20

|

1.50

|

21.00

|

12.88

|

*

|

16.50

|

12.75

|

4.63

|

7.88

|

|

14

|

25.25

|

3.38

|

16.25

|

20

|

1.63

|

22.00

|

14.14

|

*

|

17.75

|

14.00

|

5.12

|

8.38

|

|

16

|

27.75

|

3.50

|

18.50

|

20

|

1.75

|

24.25

|

16.16

|

*

|

20.00

|

16.00

|

5.25

|

8.50

|

|

18

|

31.00

|

4.00

|

21.00

|

20

|

2.00

|

27.00

|

18.18

|

*

|

22.25

|

18.00

|

6.00

|

9.00

|

|

20

|

33.75

|

4.25

|

23.00

|

20

|

2.13

|

29.50

|

20.20

|

*

|

24.50

|

20.00

|

6.25

|

9.75

|

|

24

|

41.00

|

5.50

|

27.25

|

20

|

2.63

|

35.50

|

24.25

|

*

|

29.50

|

24.00

|

8.00

|

11.50

|

|

Nominal Size

|

Outside Diameter

(OD) |

Min. Thickness

(T) |

RF Dia.

(R) |

No. of Bolt Holes

|

Diameter of Holes

|

Bolt Circle

(BC) |

So Bore ID

(SB) |

Dia. Hub Base

(HB) |

Dia. Hub Top

(HT) |

SO LTH

(SL) |

WN LTH

(WL) |

* WN Bore ID

(WB) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

1⁄2

|

4.75

|

0.88

|

1.38

|

4

|

0.88

|

3.25

|

0.88

|

1.50

|

0.84

|

1.25

|

2.38

|

*

|

|

3⁄4

|

5.12

|

1.00

|

1.69

|

4

|

0.88

|

3.50

|

1.09

|

1.75

|

1.05

|

1.38

|

2.75

|

*

|

|

1

|

5.88

|

1.12

|

2.00

|

4

|

1.00

|

4.00

|

1.36

|

2.06

|

1.32

|

1.62

|

2.88

|

*

|

|

11⁄4

|

6.25

|

1.12

|

2.50

|

4

|

1.00

|

4.38

|

1.70

|

2.50

|

1.66

|

1.62

|

2.88

|

*

|

|

11⁄2

|

7.00

|

1.25

|

2.88

|

4

|

1.12

|

4.88

|

1.95

|

2.75

|

1.90

|

1.75

|

3.25

|

*

|

|

2

|

8.50

|

1.50

|

3.63

|

8

|

1.00

|

6.50

|

2.44

|

4.12

|

2.38

|

2.25

|

4.00

|

*

|

|

21⁄2

|

9.62

|

1.62

|

4.13

|

8

|

1.12

|

7.50

|

2.94

|

4.88

|

2.88

|

2.50

|

4.12

|

*

|

|

3

|

10.50

|

1.88

|

5.00

|

8

|

1.25

|

8.00

|

–

|

5.25

|

3.50

|

–

|

4.62

|

*

|

|

4

|

12.25

|

2.12

|

6.19

|

8

|

1.38

|

9.50

|

–

|

6.38

|

4.50

|

–

|

4.88

|

*

|

|

5

|

14.75

|

2.88

|

7.31

|

8

|

1.63

|

11.50

|

–

|

7.75

|

5.56

|

–

|

6.12

|

*

|

|

6

|

15.50

|

3.25

|

8.50

|

12

|

1.50

|

12.50

|

–

|

9.00

|

6.63

|

–

|

6.75

|

*

|

|

8

|

19.00

|

3.62

|

10.63

|

12

|

1.75

|

15.50

|

–

|

11.50

|

8.63

|

–

|

8.38

|

*

|

|

10

|

23.00

|

4.25

|

12.75

|

12

|

2.00

|

19.00

|

–

|

14.50

|

10.75

|

–

|

10.00

|

*

|

|

12

|

26.50

|

4.88

|

15.00

|

16

|

2.12

|

22.50

|

–

|

17.75

|

12.75

|

–

|

11.12

|

*

|

|

14

|

29.50

|

5.25

|

16.25

|

16

|

2.38

|

25.00

|

–

|

19.50

|

14.00

|

–

|

11.75

|

*

|

|

16

|

32.50

|

5.75

|

18.50

|

16

|

2.63

|

27.75

|

–

|

21.75

|

16.00

|

–

|

12.25

|

*

|

|

18

|

36.00

|

6.38

|

21.00

|

16

|

2.88

|

30.50

|

–

|

23.50

|

18.00

|

–

|

12.88

|

*

|

|

20

|

38.75

|

7.00

|

23.00

|

16

|

3.12

|

32.75

|

–

|

25.25

|

20.00

|

–

|

14.00

|

*

|

|

24

|

46.00

|

8.00

|

27.25

|

16

|

3.63

|

39.00

|

–

|

30.00

|

24.00

|

–

|

16.00

|

*

|

|

Nominal Size

|

Outside Diameter

(OD) |

Min. Thickness

(T) |

RF Dia.

(R) |

No. of Bolt Holes

|

Diameter of Holes

|

Bolt Circle

(BC) |

Dia. Hub Base

(HB) |

Dia. Hub Top

(HT) |

SO LTH

(SL) |

WN LTH

(WL) |

* WN Bore ID

(WB) |

|---|---|---|---|---|---|---|---|---|---|---|---|

|

1⁄2

|

5.25

|

1.19

|

1.38

|

4

|

0.88

|

3.50

|

1.69

|

0.84

|

1.56

|

2.88

|

*

|

|

3⁄4

|

5.50

|

1.25

|

1.69

|

4

|

0.88

|

3.75

|

2.00

|

1.05

|

1.69

|

3.12

|

*

|

|

1

|

6.25

|

1.38

|

2.00

|

4

|

1.00

|

4.25

|

2.25

|

1.32

|

1.88

|

3.50

|

*

|

|

11⁄4

|

7.25

|

1.50

|

2.50

|

4

|

1.12

|

5.13

|

2.88

|

1.66

|

2.06

|

3.75

|

*

|

|

11⁄2

|

8.00

|

1.75

|

2.88

|

4

|

1.25

|

5.75

|

3.12

|

1.90

|

2.38

|

4.38

|

*

|

|

2

|

9.25

|

2.00

|

3.63

|

8

|

1.12

|

6.75

|

3.75

|

2.38

|

2.75

|

5.00

|

*

|

|

21⁄2

|

10.50

|

2.25

|

4.13

|

8

|

1.25

|

7.75

|

4.50

|

2.88

|

3.12

|

5.62

|

*

|

|

3

|

12.00

|

2.62

|

5.00

|

8

|

1.38

|

9.00

|

5.25

|

3.50

|

–

|

6.62

|

*

|

|

4

|

14.00

|

3.00

|

6.19

|

8

|

1.63

|

10.75

|

6.50

|

4.50

|

–

|

7.50

|

*

|

|

5

|

16.50

|

3.62

|

7.31

|

8

|

1.88

|

12.75

|

8.00

|

5.56

|

–

|

9.00

|

*

|

|

6

|

19.00

|

4.25

|

8.50

|

8

|

2.12

|

14.50

|

9.25

|

6.63

|

–

|

10.75

|

*

|

|

8

|

21.75

|

5.00

|

10.63

|

12

|

2.12

|

17.25

|

12.00

|

8.63

|

–

|

12.50

|

*

|

|

10

|

26.50

|

6.50

|

12.75

|

12

|

2.63

|

21.25

|

14.75

|

10.75

|

–

|

16.50

|

*

|

|

12

|

30.00

|

7.25

|

15.00

|

12

|

2.88

|

24.38

|

17.38

|

12.75

|

–

|

18.25

|

*

|

|

|

|

ANSI Class

|

150

|

300

|

400

|

600

|

900

|

1500

|

2500

|

|

|---|---|---|---|---|---|---|---|---|

|

Temperature oF

|

Maximum Allowable Non-Shock Pressure PSIG

|

|||||||

|

-20 to 100

|

285

|

740

|

985

|

1480

|

2220

|

3705

|

6170

|

|

|

200

|

260

|

680

|

905

|

1360

|

2035

|

3395

|

5655

|

|

|

300

|

230

|

655

|

870

|

1310

|

1965

|

3270

|

5450

|

|

|

400

|

200

|

635

|

845

|

1265

|

1900

|

3170

|

5280

|

|

|

500

|

170

|

605

|

805

|

1205

|

1810

|

3015

|

5025

|

|

|

600

|

140

|

570

|

755

|

1135

|

1705

|

2840

|

4730

|

|

|

650

|

125

|

550

|

730

|

1100

|

1650

|

2745

|

4575

|

|

|

700

|

110

|

530

|

710

|

1060

|

1590

|

2655

|

4425

|

|

|

750

|

95

|

505

|

675

|

1015

|

1520

|

2535

|

4230

|

|

|

800

|

80

|

410

|

550

|

825

|

1235

|

2055

|

3430

|

|

|

850

|

65

|

320

|

425

|

535

|

640

|

955

|

2655

|

|

|

900

|

50

|

230

|

305

|

460

|

690

|

1150

|

1915

|

|

|

950

|

35

|

135

|

185

|

275

|

410

|

685

|

1145

|

|

|

1000

|

20

|

85

|

115

|

170

|

255

|

430

|

715

|

|

Mumbai, Lucknow, Coimbatore, Imphal, Mysore, Ratlam, Delhi, Kanpur, Darjeeling, Jalandhar, Nagpur, Solapur, Kolkata, Allahabad, Dehradun, Jammu, Nashik, Srinagar, Chennai, Ahmedabad, Faridabad, Jamshedpur, Bhadravati, Chattisgarh, Durgapur, Asansol, Hospet, Bellary, Visakhapatnam, Nellore, Surat, Bangalore, Chandigarh, Ghaziabad, Jhansi, Patna, Siliguri, Hyderabad, Stainless Steel Pipe dealers in Salem, Amritsar, Noida, Kochi (Cochin), Mangalore, Indore, Vadodra, Bhubaneswar, Bikaner, Bhavnagar, Tirupur, Ankleshwar, Warangal, Agartala, Thoothukudi, Stainless Steel Pipe suppliers in Pune, Thiruvanthapuram, Jaipur, Aizawl, Guwahati, Kozhikode, Raipur, Vishakhapatnam, Jabalpur, Bhopal, Gwalior, Ludhiana, Rajahmundry, Thane, Agra, Bhubaneshwar, Gurgaon, Madurai, Rajkot, Varanasi, Bhilai, Haridwar, Meerut, Ranchi, Ahmednagar, Akola, Amravati, Aurangabad, Baramati, Beed, Bhandara, Bhiwandi, Buldhana, Chandrapur, Chimur, Dahanu, Dhule, Dindori, Erandol, Gadchiroli, Hatkanangle, Hingoli, Ichalkaranji, Jalgaon, Jalna, Karad, Khed, Yavatmal, Kolaba, Kolhapur, Kopargaon, Latur, Malegaon, Mumbai, Nagpur, Nanded, Nandurbar, Nashik, Osmanabad, Pandharpur, Parbhani, Rajapur, Ramtek, Ratnagiri, Raver, Sangli, Satara, Shirdi, Shirur, Solapur, Thane, Wardha, Washim, Andhra Pradesh, Jammu and Kashmir, Nagaland, Uttarakhand, Haryana, Lakshadweep, Arunachal Pradesh, Jharkhand, Odisha, West Bengal, Himachal Pradesh, Assam, Karnataka, Punjab, Andaman and Nicobar Islands, Puducherry, Bihar, Kerala, Rajasthan, Chandigarh, Meghalaya, Chhattisgarh, Madhya Pradesh, Sikkim, Dadar and Nagar Haveli, Mizoram, Goa, Maharashtra, Tamil Nadu, Daman and Diu, Tripura, Gujarat, Manipur, Telangana, Delhi, Uttar Pradesh in India.

United States of America, Malaysia, UAE, Indonesia, Saudi Arabia, Iran, Qatar, India, China, United Kingdom, Singapore, Canada, Thailand, South Korea, Turkey, Philippines, Egypt, Germany, Italy, Japan, Russia, Vietnam, Australia, South Africa, Portugal, Morocco, Costa Rica, Kazakhstan, Netherlands, Mexico, Brazil, France, Spain, Taiwan, Nigeria, Bangladesh, Kuwait, Iraq, Ukraine, Poland, Jordan, Romania, Oman, Hong Kong, Venezuela, Colombia, Norway, Chile, Trinidad & Tobago, Greece, Czechia, Belgium, Sri Lanka, Cyprus, Angola, Myanmar (Burma), United Kingdom, Canada, South Korea, Thailand, Netherlands, Spain, Turkey, Australia, Mexico, Pakistan, Vietnam, Brazil, Philippines, France, Taiwan, Poland, South Africa, Russia, Nigeria, Kuwait, Czechia, Norway, Romania, Egypt, Oman, Sweden, Belgium, Hong Kong, Israel, Colombia, Switzerland, Denmark, Finland, Argentina, Venezuela, Peru, Ukraine, Chile, Bangladesh, Portugal, Ireland, Austria, Algeria, Greece, Iraq, New Zealand, Slovakia, Hungary, Kazakhstan, Slovenia, Lithuania, Serbia, Sri Lanka, Bahrain, Bulgaria, Morocco, Tunisia, Croatia, Jordan, Ecuador, Trinidad & Tobago, Estonia, Azerbaijan, Ghana, Lebanon, Cyprus, Dominican Republic, Latvia, Libya, Costa Rica, Cambodia, Macedonia (FYROM), Belarus, Jamaica, Palestine, Turkmenistan